homepage /

palletizer /

Bags gripper

ROBOT GRIPPEPS FOR PALLETIZATION AND DEPALLETIZATION OF BAGS

Solaut produces grippers for palletizing and de-palletizing bags.

The palletizing grippers are divided into grippers with a single lateral comb or a double comb.

Solaut also produces gripping devices for boxes, sheets and panels, for bottles and flacons;

the links to the dedicated pages are listed below:

Solaut produces 3 types of bag grippers that we can supply together with our palletisers or even separately.

We also supply accessories such as roller conveyors and groups for leveling bags.

The types of bag grippers we produce are:

Accessories for palletizing bags:

Download the pdf catalog of grippers.

click for more images

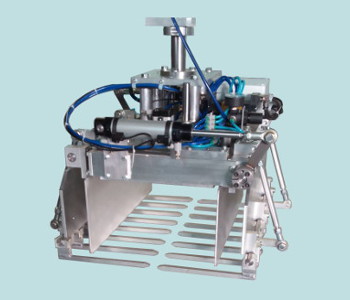

GRIPPERS FOR BAGS WITH A SIDE COMB

Our grippers are always adaptable to customer needs. The data we report below are indicative.

The pitch of the elements of the lateral comb is 80mm (pitch of the feed roller conveyor).

The gripper is equipped with two side plates that laterally delimit the bag: a plates is fixed and one is mobile.

During gripping the movable plate widens to facilitate the insertion of the gripper over the bag.

The sheet closes on the bag to delimit its lateral dimensions.

The fixed plate can be enlarged or tightened by moving the fixing holes.

The side comb grippers are available in the following versions:

- comb from 5 to 10 elements

- two versions for bags up to 30Kg and up to 50Kg

- with compactor plate

- with suction pads to hold the pallet slip sheet

- gripper with pallet hooks

- gripper with actuator for rotation: 0-90°.

This type of gripper is an economical solution for palletizing bags with poor consistency.

This type of pliers allows an excellent formation of the layer at the expense of a speed that is not extremely high,

due to the time required to remove the comb from under the bag.

The compactor plate is used to flatten soft and non-uniform bags:

it can be used both in grip and to press the bag once deposited on a pallet.

click for more images

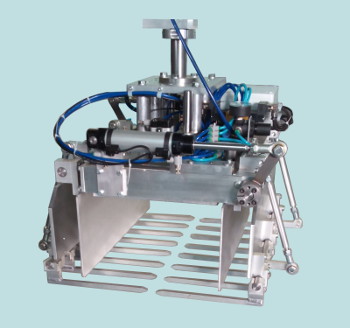

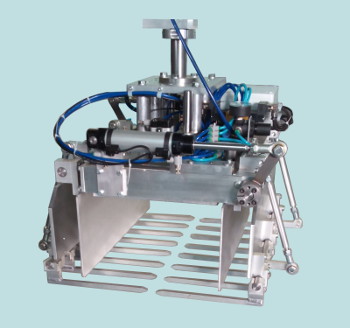

GRIPPERS FOR BAGS WITH TWO COMBS

The robot grippers for palletizing bags with two combs are particularly suitable for those applications

where the release speed is a determining factor.

As for the side comb model, there are two plates for lateral containment of the bag.

Both side plates are movable: in the gripping phase they delimit the bag, while in release they guide the fall.

The gripper can be supplied complete with a compacting plate, pick-up hooks for pallets and slip sheet suction pads.

Grippers available in the following versions:

- comb from 5 to 10 elements

- two versions for bags up to 30Kg and up to 50Kg

- with compactor plate

- gripper with suction pads to hold the slip sheet

- gripper with pallet hooks

- gripper with actuator for 0-90° rotation.

click for more images

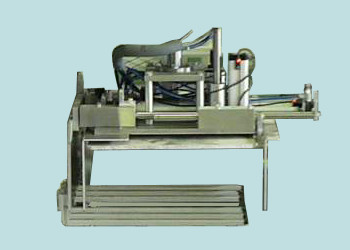

GRIPPERS FOR DEPALLETIZING BAGS.

The figure to the side shows a gipper for depalletizing bags.

The gripping element consists of a suction cup and two pairs of hooks.

The suction cup is placed on the bag and if the gripping position is correct, it can lift the bag.

Just after removing the bag from the pallet, two pairs of hooks close mechanically fixing the bag to the gripping element.

The bag can be carried on the product discharge tanks to be cut by a special blade.

The bag of the bag is unloaded separately (eg in a compacting press).

click for more images

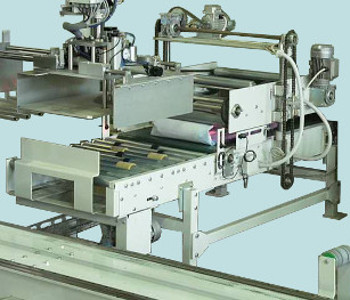

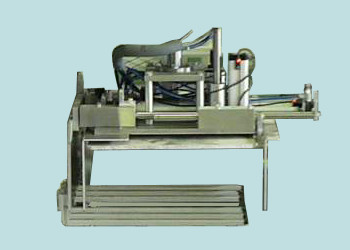

BAG FLATTENER

In the figure on the side there is a flattening device for bags useful for preparing the bags before they are palletized..

Manually filled bags have an accumulation of material in the lower part.

To obtain a uniform palletization, the bag flattener levels the upper surface of the bag

to allow subsequent bags to find a sufficiently flat supporting surface.