homepage /

palletizer /

slip sheet dispenser

RAIL SLIP SHEET DISPENSER

This product is suitable for all applications where pallet divider is required

on multiple palletizing stations.

The machine picks up the pallet slip sheet from a single warehouse.

The palletizing stations can belong to a single machine or belong to several palletizers.

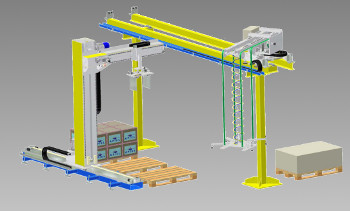

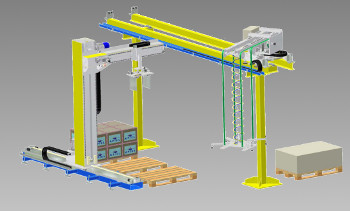

The figure on the side shows a palletizer operating on 3 pallet places with

the dispenser in the sheet pick phase.

Once positioning is complete, the gripping head is lifted, retracted so as to move out of the space

occupied by the palletizer and thus allow the palletizer to work

and the slip sheet dispenser to pick up a new layer.

The same machine can be used on depalletizers, for removing pallet divider.

The types of rail slip sheet dispenser that we produce are:

Download the pdf catalog of rail slip sheet dispenser

click for more images

STRAIGHT RAIL SLIP SHEET DISPENSER

The constituent elements of the straight rail slip sheet dispenser are:

the rail, the carriage and the electrical panel on the ground.

The rail consists of a pair of double T 500mm pitch beams.

The rail must be positioned above the palletizer frames.

The carriage runs on the rails using rubber wheels.

The carriage is self-propelled: on board we have the motor for translation on the rail,

the PLC for controlling both translation and all movements,

the gripping head with suction cups for hooking the pallet divider,

the winch for vertical handling of the gripping head

and the gripping head positioning arm.

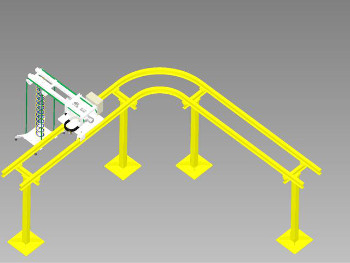

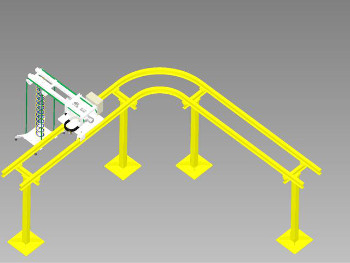

CURVILINE RAILWAY SLIP SHEET DISPENSER

The rail consists of a pair of double T beams 500mm pitch.

An electrified track is fixed to the rail to feed the carriage.

The rail is made up of straight sections and curves that make it possible to achieve

the path necessary to reach all points of the installation.

The electrical panel on the ground contains the electromechanical and safety elements

of the power supply of the trolley through the electrified track.

The slip sheet dispenser command is realized with an operator panel connected to the trolley

by means of a wireless ethernet connection.

Communication with the rest of the system can take place via I/O Ethernet modules

or through a second PLC also equipped with an Ethernet port.

The trolley is shaped and installed to be able to move freely from one position

to the other of the system, without interfering with the moving parts of the palletizer.

The arm of the trolley that carries the gripping head can rotate in the horizontal plane.

The carriage moves to the side of the slip sheet warehouse;

the arm rotates to bring the gripping head in axis with the slip sheet stack.

The winch lowers the gripping head until it reaches the first slip sheet;

the head by means of 4 suction cups hooks the sheet and raises it.

Once the lifting is complete, the arm rotates to bring the head into the translational position

Start the translation movement of the trolley towards the point of application of the flap.

Once the point is reached, the trolley awaits the consent of the palletizer.

Once the command has been carried out, the arm rotates to bring the slip sheet in axis with the pallet;

the winch lowers the sheet on the pallet.

Once the release is completed, the head rises and the rotation of the arm is completed,

the consent is sent for resuming the palletisation.